1. The mud pump must be installed on a relatively stable foundation. Before operation, carefully check the lubrication condition, fastening condition, and fit clearances between various parts of the pump. Also pay attention to check whether the inlet pipe and outlet pipe are clogged or not. Be sure that the bottom valve can be opened and closed freely. Check the each part of seals to prevent water and air leakage.

2. The particle size of the slurry during the construction transportation process is related to the service life of the vulnerable parts of the mud pump. Avoid big particles of slurry clogging the mud pump. In order to reduce the construction investment and improve the production efficiency, we must frequently inspect and replace the vulnerable parts, or use advanced anti-wear technology measures to increase the service life of the vulnerable parts.

3. The daily maintenance of the mud pump is preferably carried out by a professional technician, and equipped with frequently used and easily damaged components.

4. Every two years, the mud pump is supposed to take a complete dismantling inspection to perform maintenance or repair, or directly replace the mud pump. It is also necessary to regularly pump the mud pump in order to extend its service life.

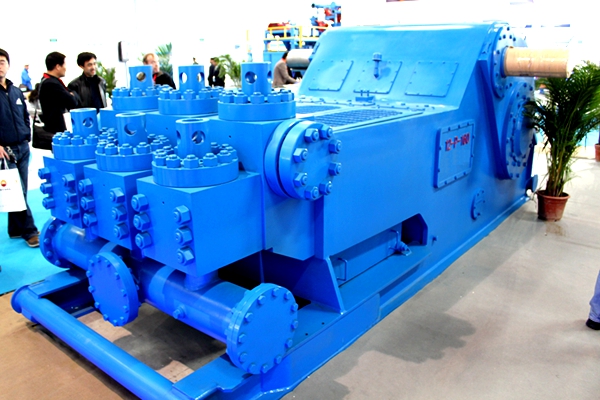

9 P 100 Mud Pump